Luxury watches get a new lease of life at our state-of-the-art service centre

So giving them the right care and attention, extending their life as long as possible, is crucial.

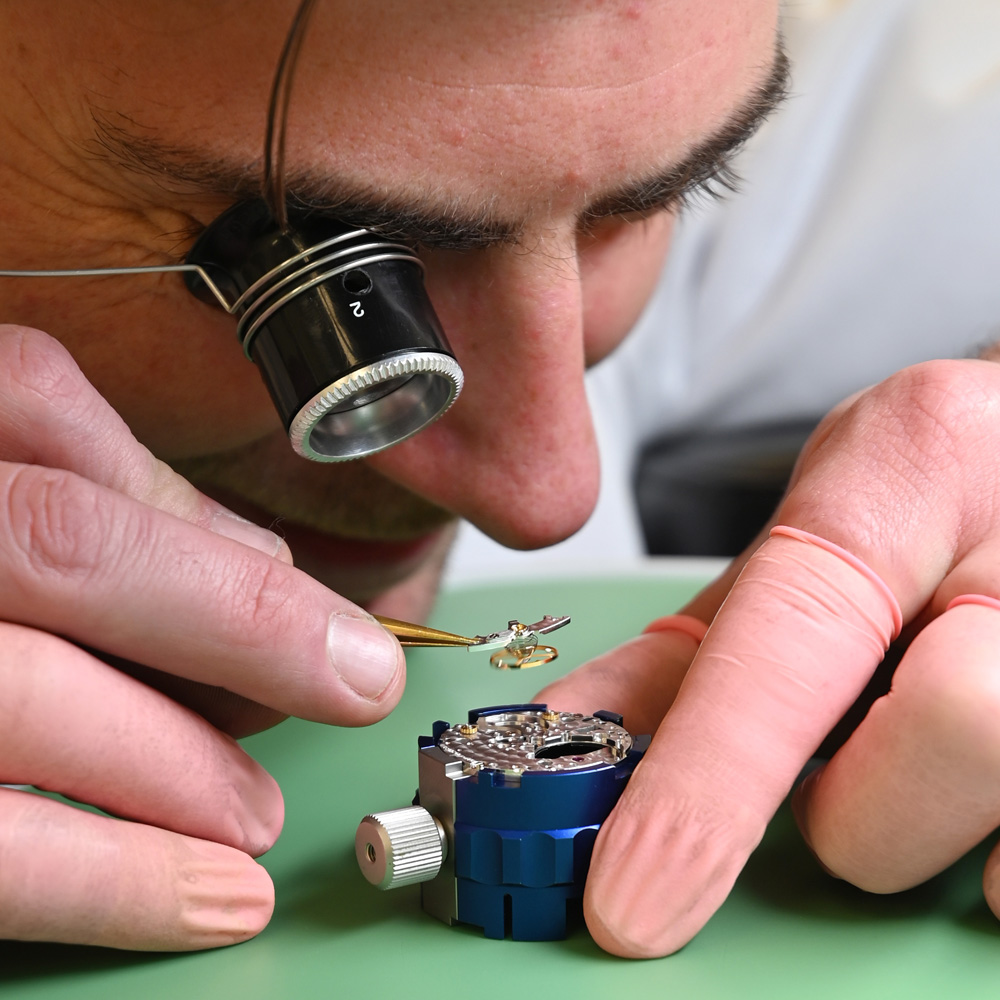

Take a look inside the fascinating workings of our watch workshop and meet our watchmaker to see exactly how we can help.

The home for luxury watch repair

Our watch workshop was extended and refurbished just a few months ago to the very highest specifications.

It now includes a dedicated polishing room, where watch cases and bracelets are refinished and lustre restored.

As well as this there is also a separate cleaning room for the tiny parts which make up a mechanical watch movement. This is where pressure testing also takes place, ensuring that watches are sealed adequately against water and dust ingress.

This is important because the team reseals watches which are waterproof to a certain depth.

H. L. Brown’s expert watchmaker Matthew Ardron said:

“We have spent a huge amount of time and effort on refurbishing the workshop. Everything is to an incredibly high specification. I think it would be fair to say this is the most state-of-the-art watch workshop in South Yorkshire.”

What kind of watch repairs are most common?

Just like cars, luxury watches need regular upkeep due to their many parts.

Much of the watch servicing and watch restoration work which comes in to our workshop is for mechanical watches which are powered by a mainspring.

Matthew said: “These mechanical components are naturally going to show signs of wear. Eventually it gets to the point where they don’t work.

“We are able to strip a watch down, investigate every part to find out what is happening and then rebuild it again.

“Some parts may need replacing, we will refinish the case, and then the customer may have another ten years of happiness from a treasured possession.”

For non-mechanical watches, the workshop also replaces batteries, crowns and seals that guarantee water resistance.

Matthew explained that OMEGA Co-axial watches can also be repaired at the workshop. Co-axial watches use a different type of escapement mechanism called a co-axial. Invented by a Briton, George Daniels, in 1976, that was a major development in watchmaking and still is at the present time.

Matthew added: “Co-axial watches have a type of escapement which don’t require lubricant but they are very complex. To work on these kind of watches you need a microscope and special tooling, which we have here.”

Why we love restoring luxury watches

Taking your time is key when it comes to restoring or repairing luxury watches because they are an investment as well as a thing of beauty. Collectors can be sure their timepieces are in good hands at H. L. Brown.

Matthew has been trained to the highest standards and holds many qualifications, including from the British School of Watchmaking and internationally, WOSTEP.

Matthew said: “Watchmaking really suits my personality and I love everything about it. You really have to concentrate and be very critical, making sure everything is perfect. If you are patient and like taking your time it is a very rewarding job. It is like mindfulness but doing it as a full-time job.”

And as for the more unusual timepieces brought in by watch collectors, some are a reminder of H. L. Brown’s proud history as a Sheffield jeweller. The business was founded back in 1861.

Matthew added: “Sometimes people bring in vintage pocket watches that are 100 to 150 years old and say H. L. Brown on the back.

“It’s always great to see those coming back into the store.”